Call Us: WA | +61 (0) 8 92091132 / QLD | +61 (0) 7 3185 2175 / email us | sales@caldertech.com.au

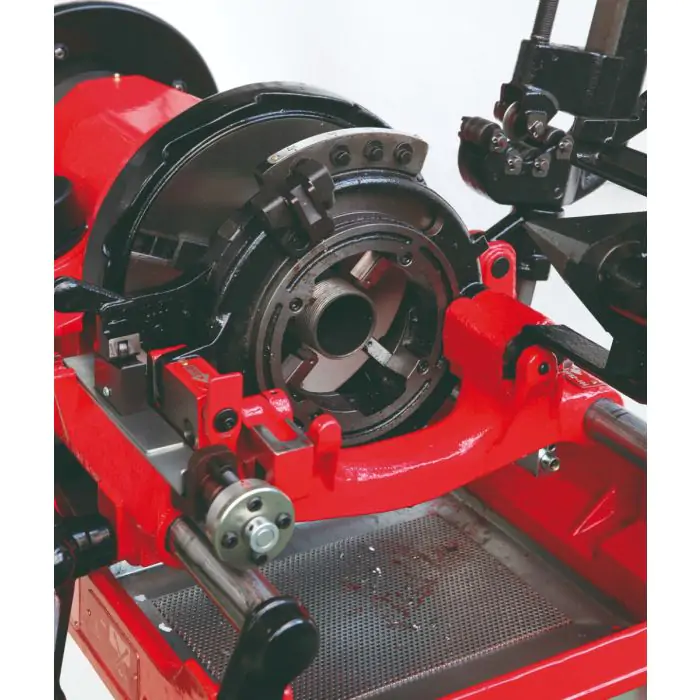

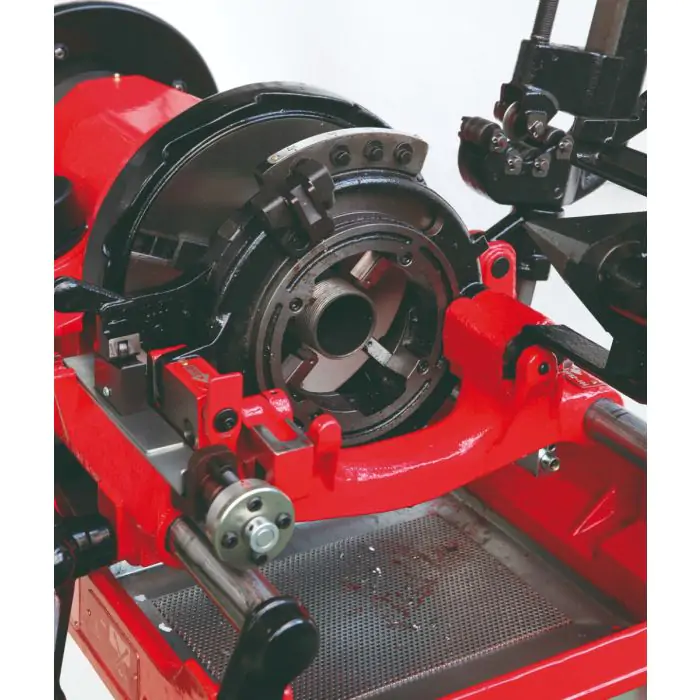

Threading Machine 4″

Quick, simple thread size adjustment.

Hammer-type chuck and long jaws to rapidly, firmly and safely secure the pipe.

- PRODUCT DESCRIPTION

- ACCESORIES

- DOCUMENTS DOWNLOADS

Machine producing “gas” threads with sealing as per NFE 03.004 compliant with ISO/7.

For tubes complying with the EN 10255 S and EN 10255 W standards (former NFA 49115 and NFA 49145 standard medium and heavy duty series); only light series tubes are not recommended.

Self-priming gear-style oil pump.

Raised strainer avoids oil contamination by iron filings.

Variable oil flow control.

Heavy-duty dies available in HSS and standard grade steel.

Slotted dies for quick and easy replacement without removing the head.

3 gears for optimum cutting and threading of each pipe diameter.

Safety pedal for starting and stopping the machine.

Three-blade reamer for a precision result.

Special storage compartment.

A machine of proven endurance, designed for high-volume applications.

| Capacity | Steel: BSPT, NPT Ø 1/4″ – 4″. BSPP Ø 1/2″ – 2″. Stainless steel: BSPT, NPT Ø 1/4″- 4″. |

|---|---|

| Tips | Use specially-designed dies and cutting wheels when working with zinc-coated and stainless steel. |

| Supplied with | – 1 automatic 1/2″ to 2″ BSPT threading head, – 1 automatic 2.1/2″ to 4″ BSPT threading head, – 1 set of right-hand BSPT dies 1/2″ – 3/4″, – 1 set of right-hand BSPT dies 1″ – 2″, – 1 set of right-hand BSPT dies 2.1/2″ – 4″, – 1 steel pipe cutting wheel, – 4 support legs, – 1 safety pedal. |

| Sku | Motor | Power W | Composition | Dies | Speed rpm | Size mm | kg |

|---|---|---|---|---|---|---|---|

| 162140 | Single-phase induction 230 V motor | 1600 | Ø”: 1/2 – 3/4, 1 – 2, 2.1/2 – 4. Ø mm: 8/13 – 12/17, 26/34 – 50/60, 66/76 – 102/114 | Right-hand BSPT | 36/20/11 | 1200 x 870 x 1200 | 142,200 |

WHATEVER YOUR REQUIREMENTS.

HIRE IT FROM US!

Caldertech Australia now offers a full hire service.

All the poly pipe fusion products and equipment you need to get the job done right, now available at competitive Hire Rates.

Available for daily, weekly or monthly hire, we have a wide range of equipment from Electrofusion Welders and Butt Fusion Machines, to Ancillary Tooling guaranteed to meet your job requirements.

In addition to our well-know support, we also offer Hire Packages and Kits such as Welder, Clamp and Scraper Kits, so you know we are your one stop-shop to get all the equipment you need to get the job done.

Simply fill in the form , detailing your job needs or reference the equipment you are after, and one of our specialists will contact you within 24hrs. You can find all our equipment in our Products Page.

© Caldertech Australia 2025. ABN 22 164 140 630. All Rights Reserved.