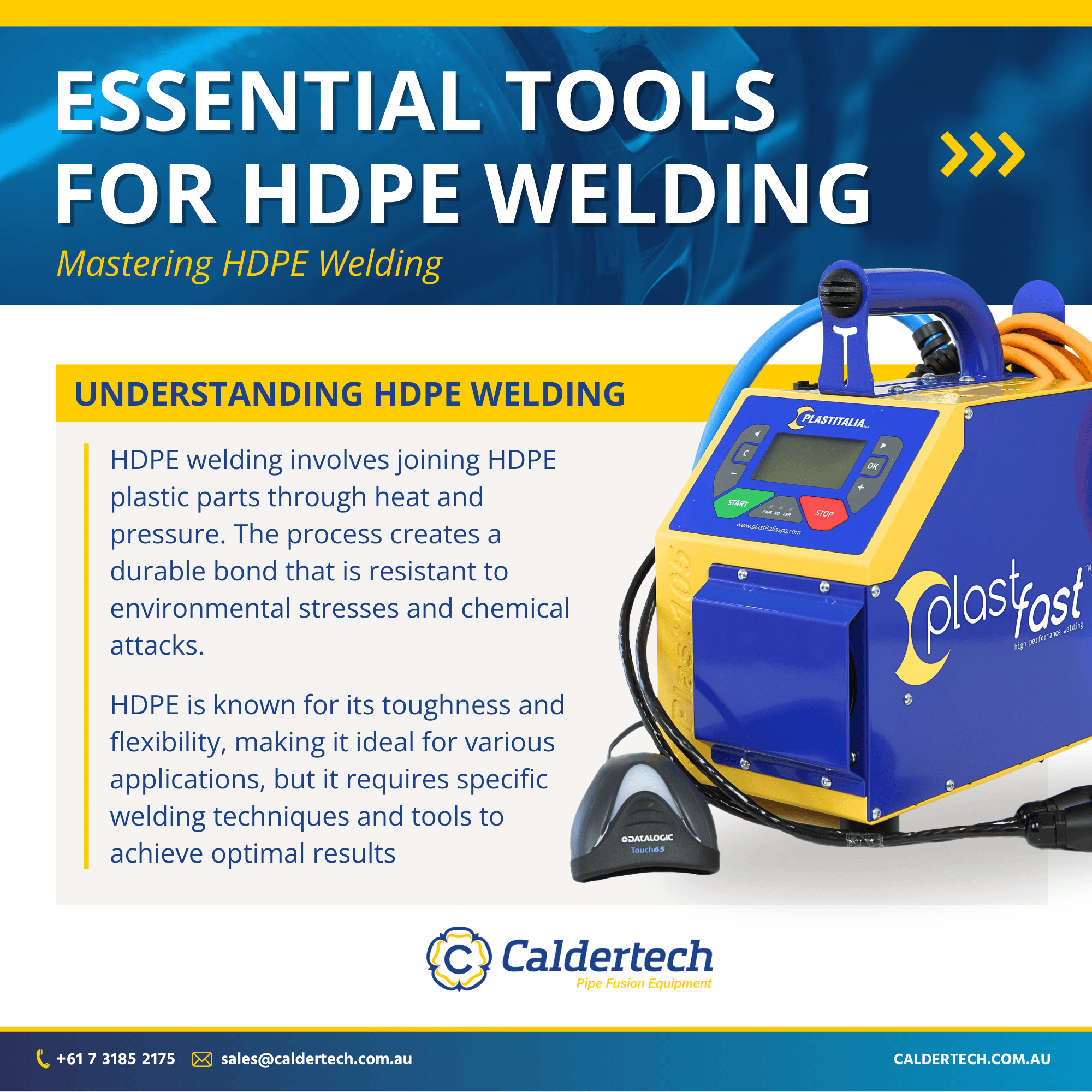

High-Density Polyethylene (HDPE) welding is a crucial process in various industries, including construction, pipeline installation, and plastic fabrication. Mastering this technique involves understanding the material, using the right tools, and applying precise methods to ensure strong, reliable welds. This guide explores essential techniques and tools for successful HDPE welding.

HDPE welding involves joining HDPE plastic parts through heat and pressure. The process creates a durable bond that is resistant to environmental stresses and chemical attacks. HDPE is known for its toughness and flexibility, making it ideal for various applications, but it requires specific welding techniques to achieve optimal results.

Cleaning: Ensure that the surfaces to be welded are clean and free from contaminants like dirt, grease, and moisture. Use appropriate cleaning agents to achieve a spotless surface.

Surface Preparation:

For effective bonding, roughen the surfaces slightly if they are too smooth. This increases the surface area and enhances the adhesion.

Preheating Temperature:

Some HDPE materials benefit from preheating before welding. This helps to reduce thermal stress and improve weld quality. Generally, preheating temperatures range from 50°C to 100°C (122°F to 212°F), depending on the specific material and application.

Welding Methods

Butt Welding:

This method involves aligning two HDPE pieces and heating their edges until they melt, then pressing them together to form a weld. It’s ideal for joining large sections or creating strong joints.

Extrusion Welding:

In extrusion welding, a filler rod of HDPE is melted and fed into the joint while heating elements maintain the required temperature. This method is used for welding thicker sections or for adding material to existing welds.

Socket Welding: Used for joining pipes or tubes, socket welding involves inserting one piece into another and applying heat to create a strong, leak-proof joint.

Temperature Control

Monitoring: Use accurate temperature control to ensure consistent welding conditions. Both too high and too low temperatures can adversely affect the weld quality. Typically, HDPE welding is done at temperatures between 200°C and 260°C (392°F to 500°F).

Pressure Application

Pressure Settings: Applying the right amount of pressure is crucial to achieving a proper weld. Insufficient pressure may result in weak joints, while excessive pressure can cause material deformation. Follow manufacturer guidelines for pressure settings.

Cooling and Post-Weld Care

Cooling Time: Allow the weld to cool gradually to avoid stress and potential deformation. Rapid cooling can lead to weak joints and other defects.

Inspection: After cooling, inspect the weld for any signs of defects such as gaps, voids, or inconsistent bonding.

Essential Tools for HDPE Welding

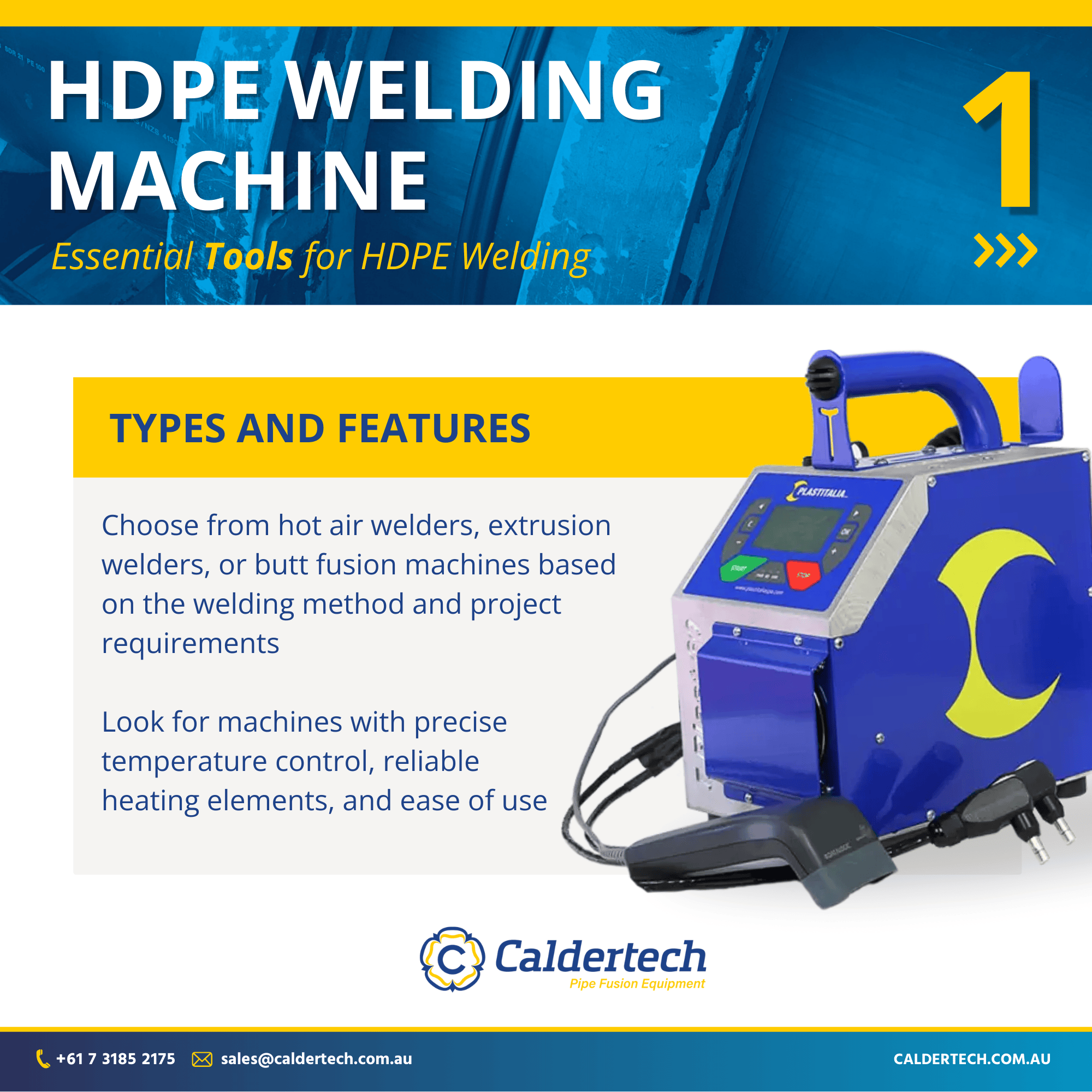

HDPE Welding Machine

Types: Choose from hot air welders, extrusion welders, or butt fusion machines based on the welding method and project requirements.

Features: Look for machines with precise temperature control, reliable heating elements, and ease of use.

Welding Rods and Consumables

Rod Selection: Use HDPE welding rods that match the base material’s specifications. Ensure they are clean and free of contaminants.

Consumables: Regularly replace nozzles, heating elements, and other consumables to maintain weld quality.

Temperature Measurement Tools

Thermometers and Pyrometers: Accurate temperature measurement is essential for consistent welding results. Use digital thermometers or infrared pyrometers to monitor and control temperatures.

Surface Preparation Tools

Cleaning Agents: Use appropriate solvents and detergents to clean the surfaces before welding.

Surface Rouging Tools: If necessary, use abrasive tools to roughen the surfaces for better adhesion.

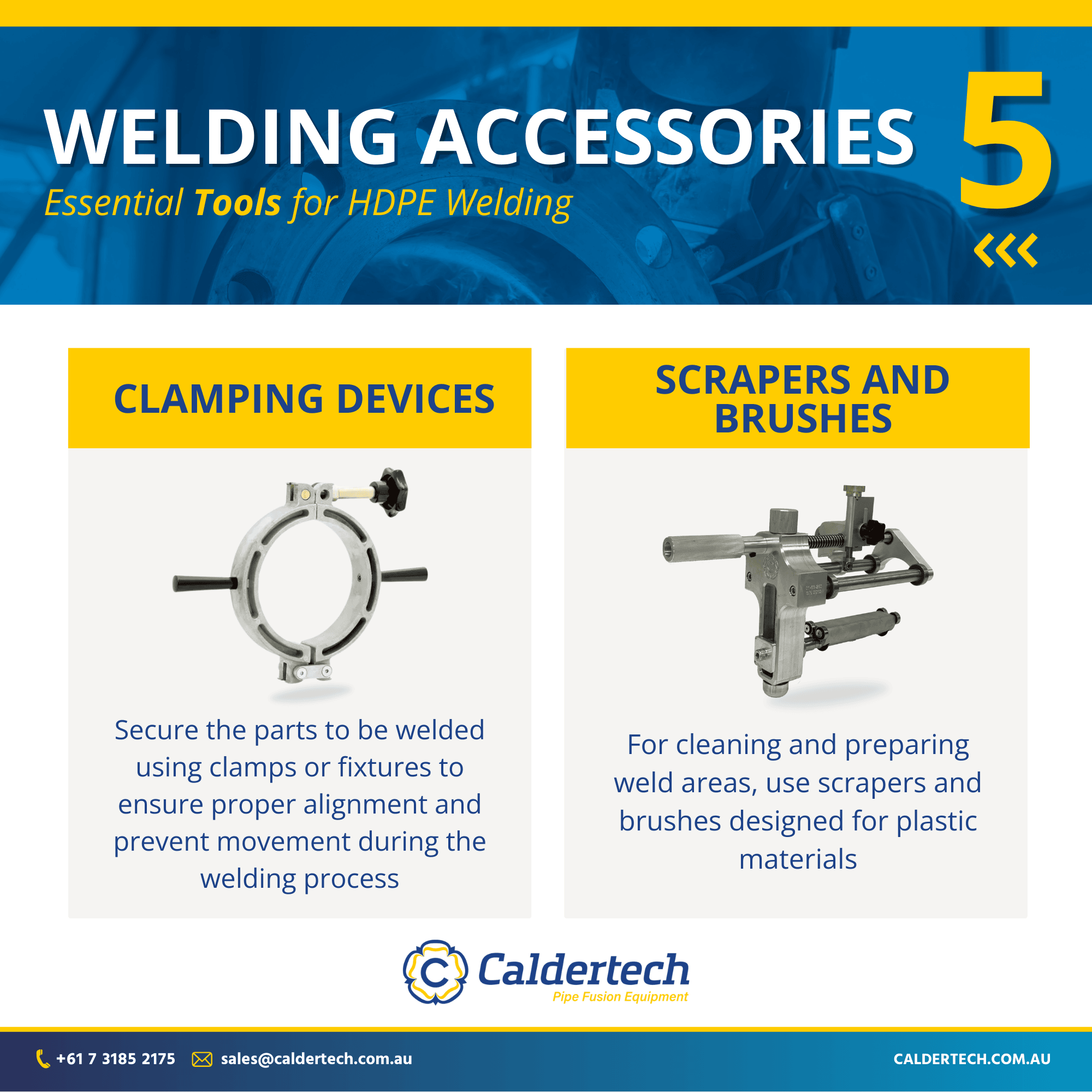

Welding Accessories

Clamping Devices: Secure the parts to be welded using clamps or fixtures to ensure proper alignment and prevent movement during the welding process.

Scrapers and Brushes: For cleaning and preparing weld areas, use scrapers and brushes designed for plastic materials.

Conclusion

Mastering HDPE welding requires a blend of technical knowledge, skillful technique, and the right tools. By understanding and applying the essential techniques and using the proper equipment, you can achieve high-quality, durable welds that meet your project’s requirements. Continuous practice and staying updated with industry advancements will