Cutting polypipe, commonly used in plumbing, irrigation, and other piping systems, may seem straightforward, but choosing the right tool is crucial for achieving precise, clean cuts. A well-selected polypipe cutter can save you time, reduce waste, and ensure that your installations are free from leaks and other issues. This guide will walk you through everything […]

High-Density Polyethylene (HDPE) welding is a critical process in various industries, from water and gas piping to chemical storage and infrastructure projects. Despite its robustness, even the best HDPE welding equipment can encounter issues that can compromise the quality of welds and the integrity of installations. This article delves into common problems encountered with HDPE […]

High-Density Polyethylene (HDPE) welding is a crucial process in various industries, including construction, pipeline installation, and plastic fabrication. Mastering this technique involves understanding the material, using the right tools, and applying precise methods to ensure strong, reliable welds. This guide explores essential techniques and tools for successful HDPE welding. HDPE welding involves joining HDPE plastic […]

High-Density Polyethylene (HDPE) welding is a crucial process in various industries, including construction, pipeline installation, and plastic fabrication. Mastering this technique involves understanding the material, using the right tools, and applying precise methods to ensure strong, reliable welds. This guide explores essential techniques and tools for successful HDPE welding. HDPE welding involves joining HDPE plastic […]

1. Electrofusion must not be used if the operator suspects that a gaseous atmosphere is present. This must be checked using an approved gas detector prior to the weld to confirm that the gas readings remain below 20% LEL (Lower Explosive Limit). 2. If the fusion stops mid-weld, allow the fitting and pipe to cool […]

Did You Know? Proper Pipe Preparation is Key to Successful Electrofusion Welding! When working with HDPE pipes, peeling or scraping is a crucial step to ensure a strong, reliable weld. Here’s why: Why Peeling Matters: Removes Oxidized Layer: HDPE pipes develop an oxidized layer on the surface when exposed to air. This layer must be […]

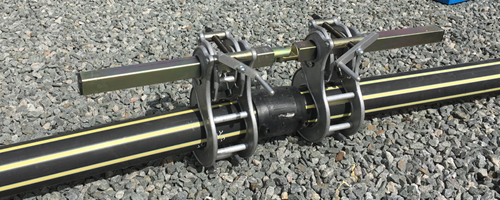

In electrofusion welding, particularly for polyethylene (PE) pipes, using the correct clamps is essential to ensure the pipes are held securely in place during the welding process. The primary purpose of clamps in electrofusion welding is to prevent pipe movement and ensure proper alignment and contact between the pipe and the electrofusion fitting. Here are […]

When buying an electrofusion welder, it’s crucial to consider several factors to ensure you get a reliable, efficient, and suitable device for your specific needs. Here are the key aspects to look for: 1. Compatibility and Capacity Pipe Size Range: Ensure the welder can handle the range of pipe diameters you typically work with.Material […]

Peeling or scraping HDPE (High-Density Polyethylene) pipe is an essential step in preparing for electrofusion welding. This process removes the oxidized layer and any surface contaminants to ensure a proper and secure weld. Here’s a step-by-step guide on how to properly peel/scrape HDPE pipe for electrofusion welding: Tools and Materials Needed: Rotary pipe peeler […]