1. Electrofusion must not be used if the operator suspects that a gaseous atmosphere is present. This must be checked using an approved gas detector prior to the weld to confirm that the gas readings remain below 20% LEL (Lower Explosive Limit).

2. If the fusion stops mid-weld, allow the fitting and pipe to cool down then cut out the fitting and start again. DO NOT RE-FUSE FITTINGS.

3. Ensure That the fittings remain in their protective bags until immediately prior to use.

4. A suitable location that is flat and dry must be used to carry out the weld fittings that are standing in water or are wet.

5. Protect the joint from wind chill effects by using pipe ends during cold or windy conditions.

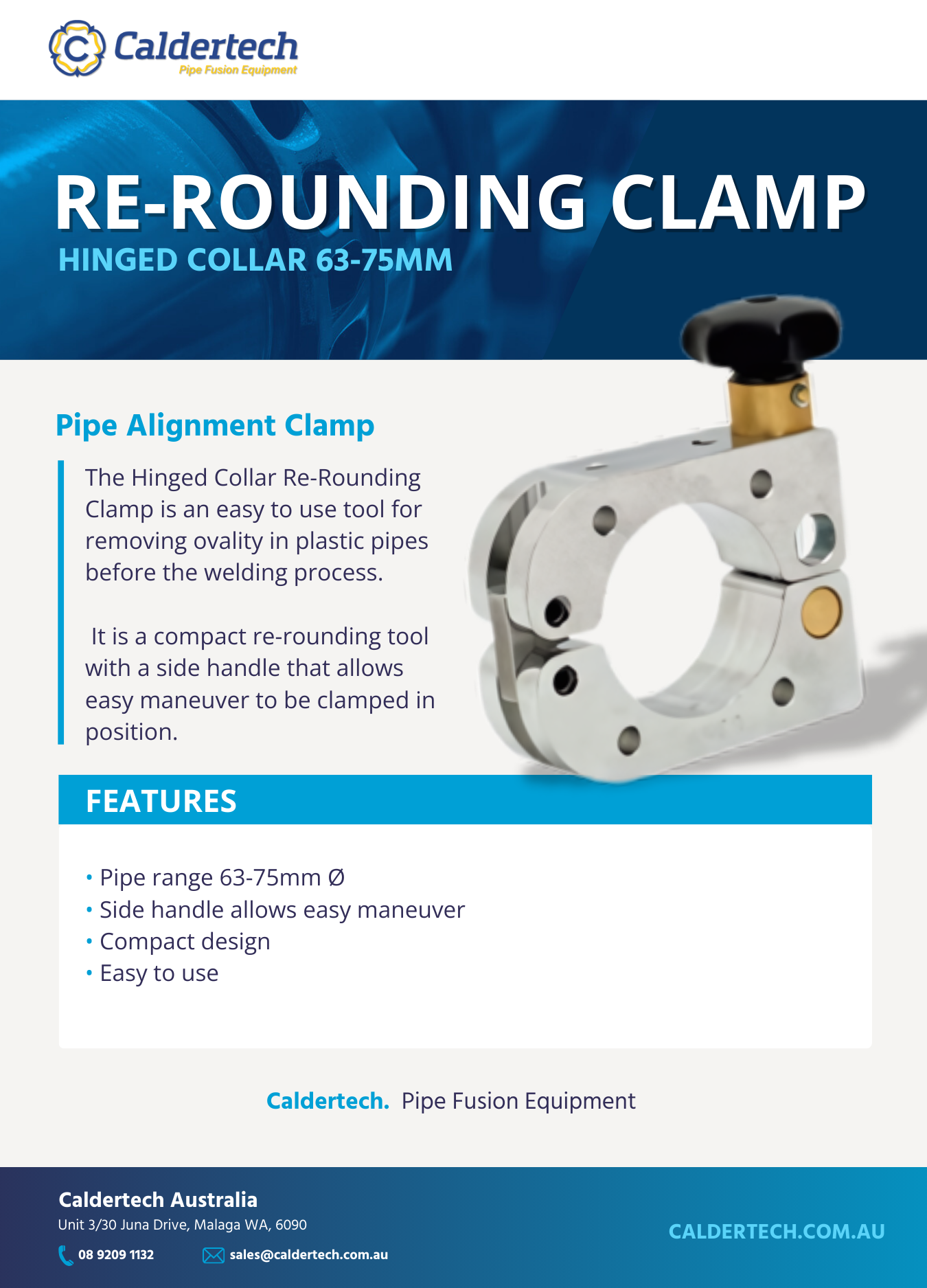

6. The pipe should be checked for ovality prior to fusing and a re-rounding tool used where necessary.

7. Always use the correct size of fitting for the pipe being used.

8. Do not weld if the ambient temperature is less than -5 degree Celsius or greater than 40 degree Celsius.

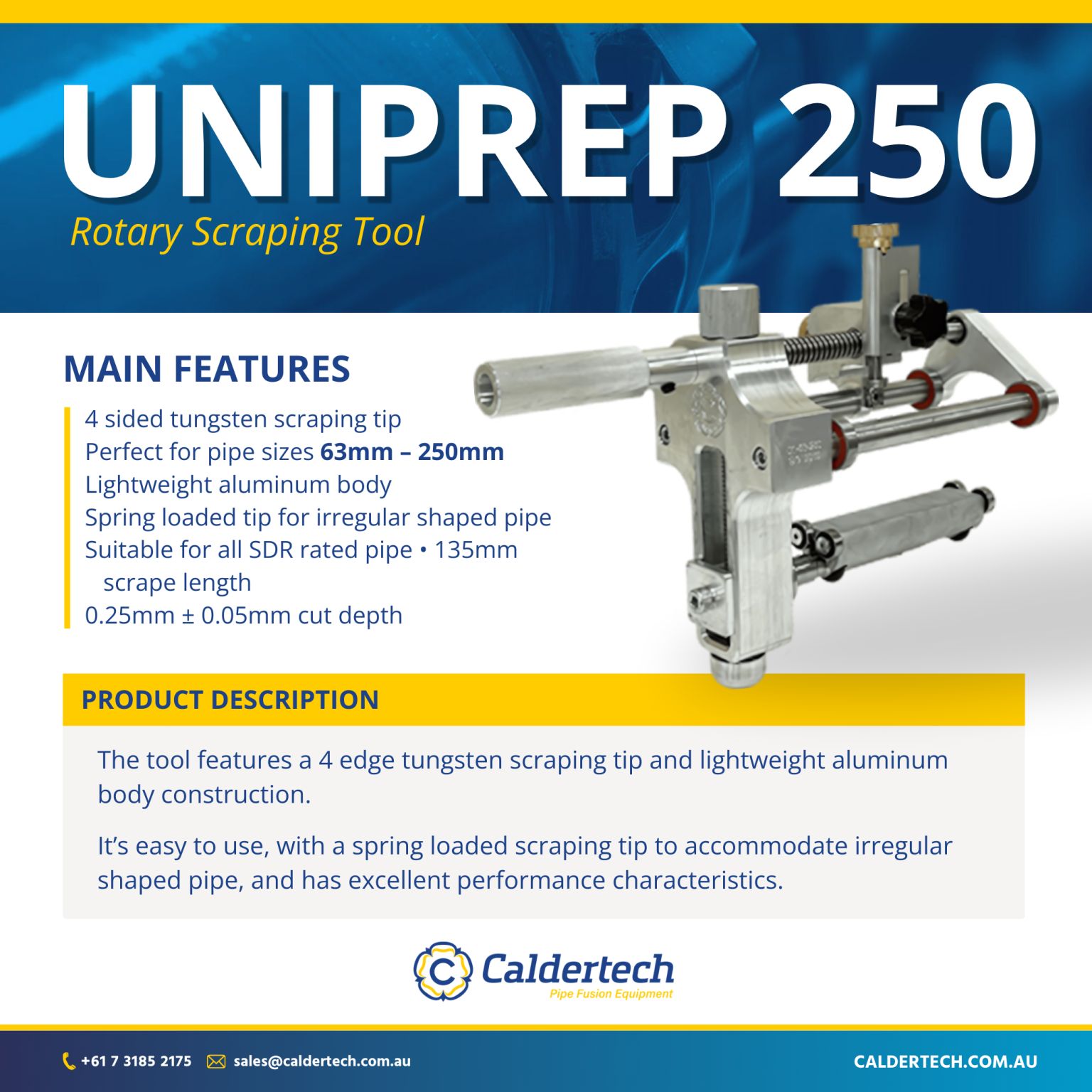

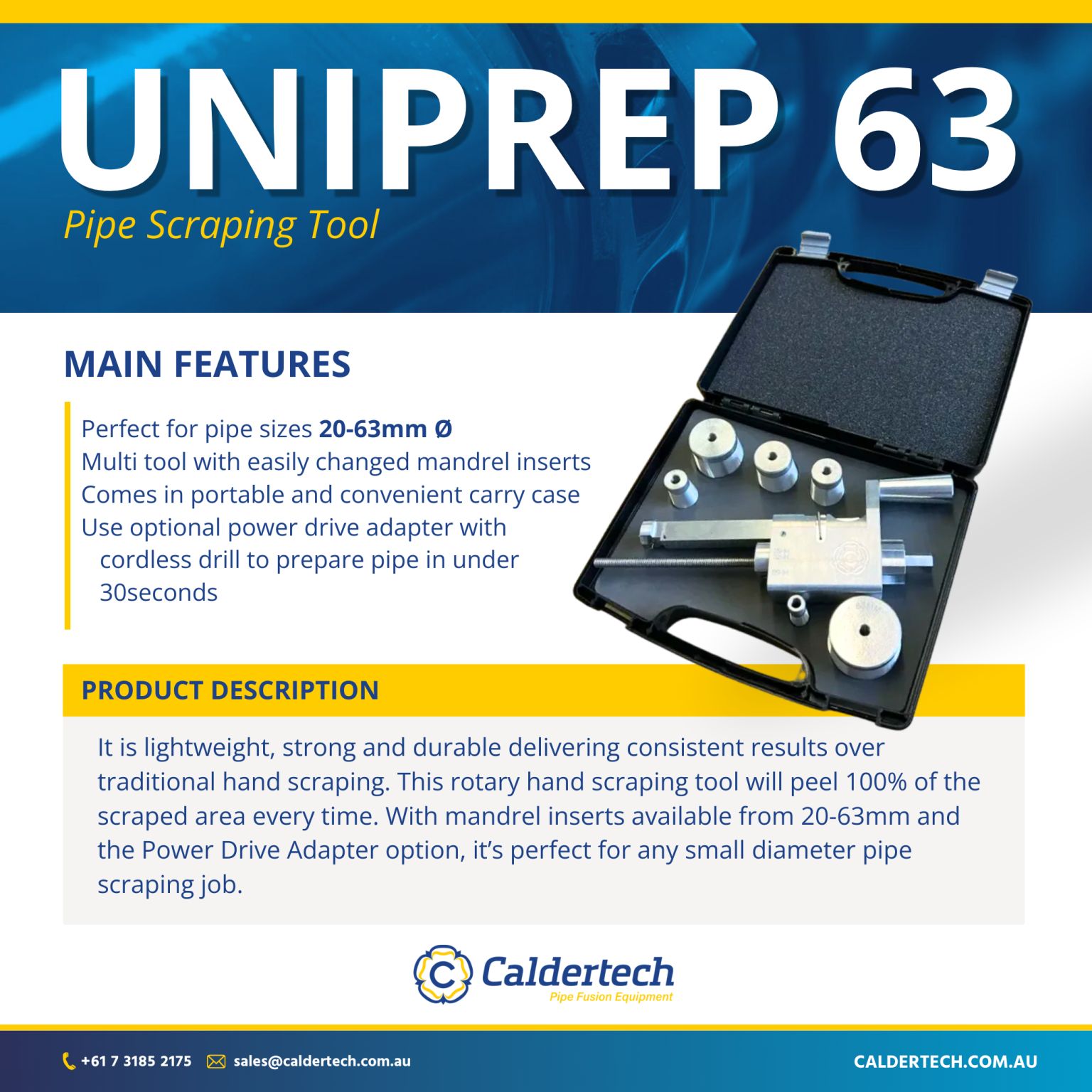

9. Do not scrape any surface containing a heating element.

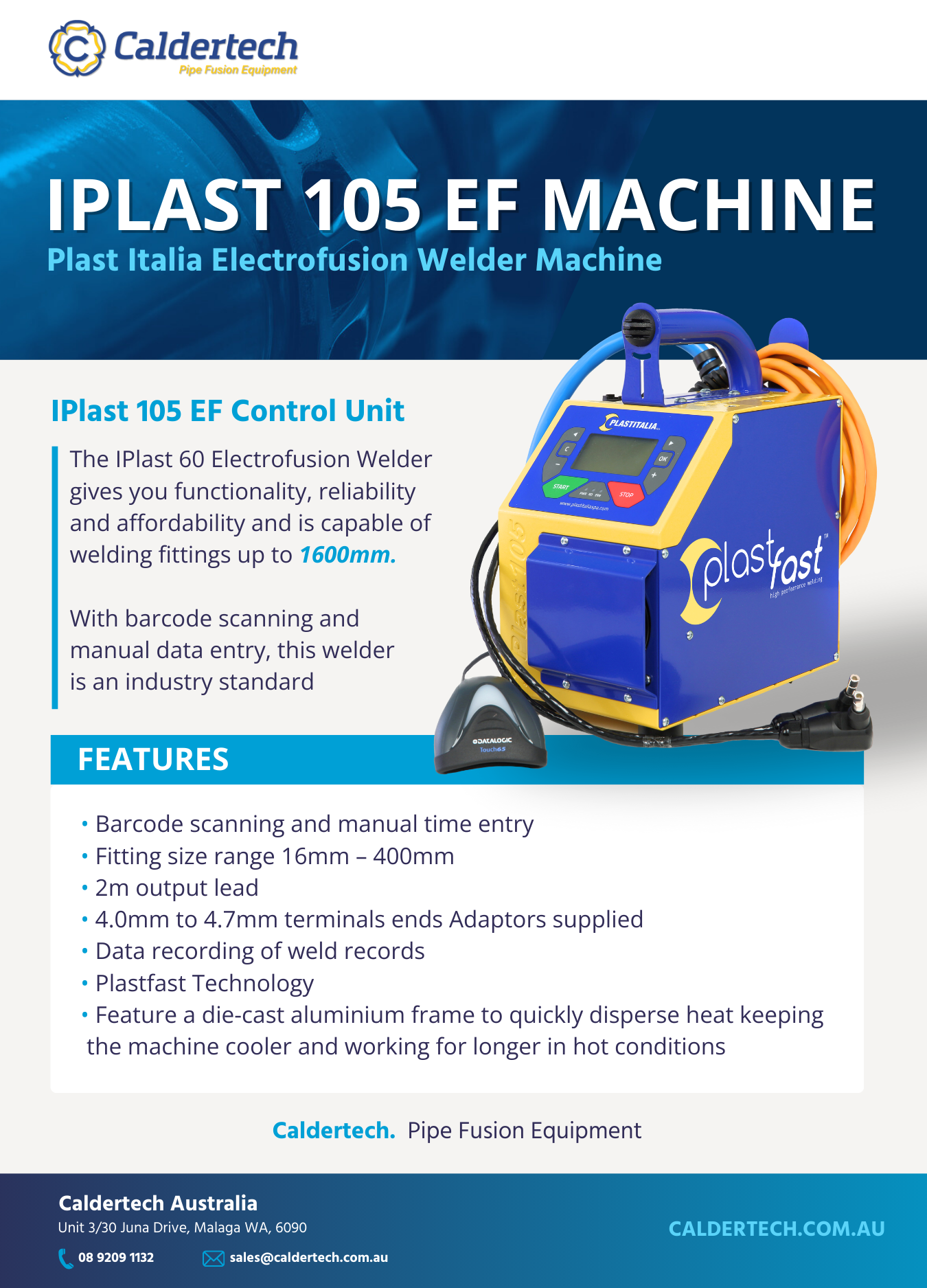

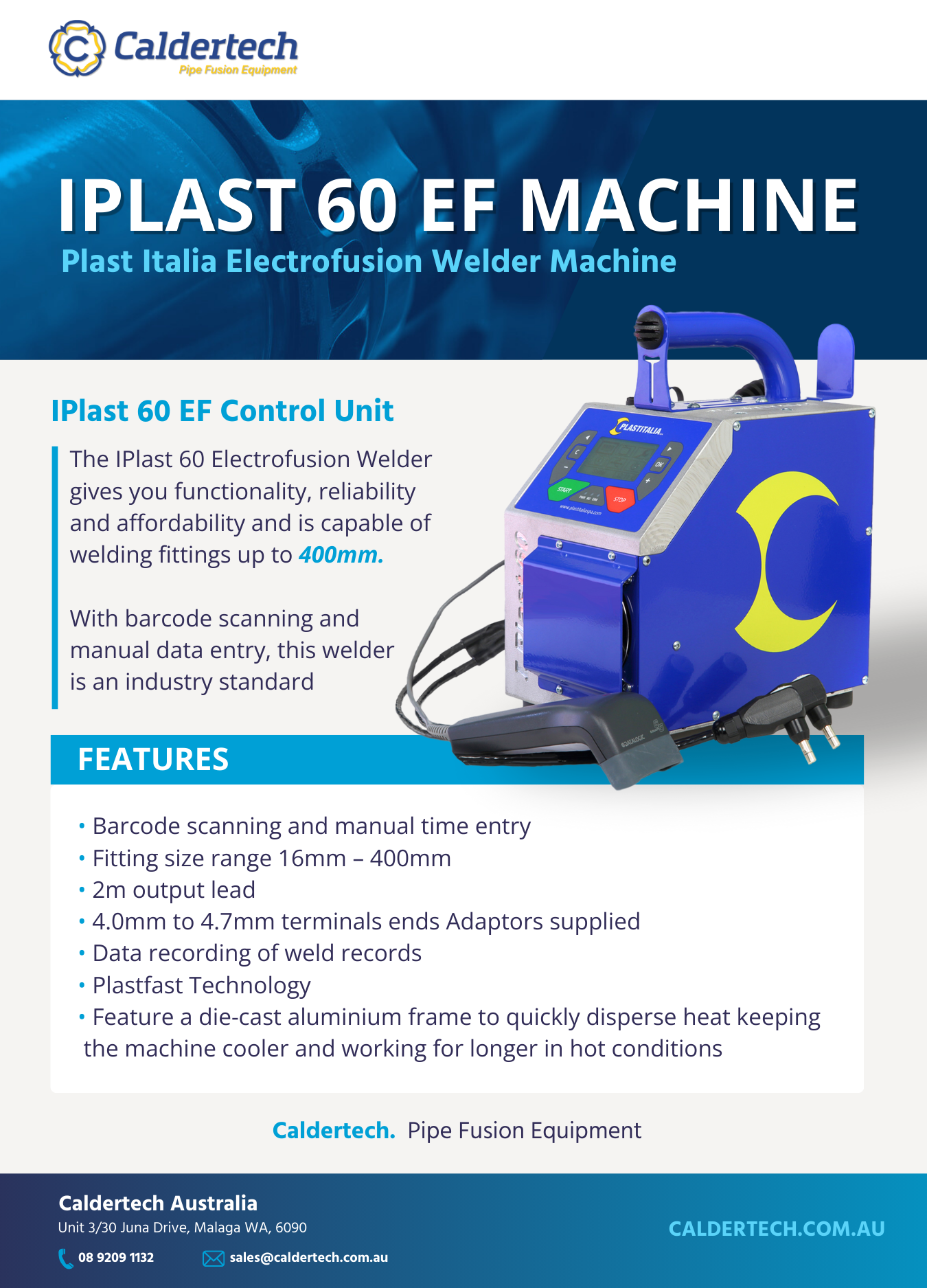

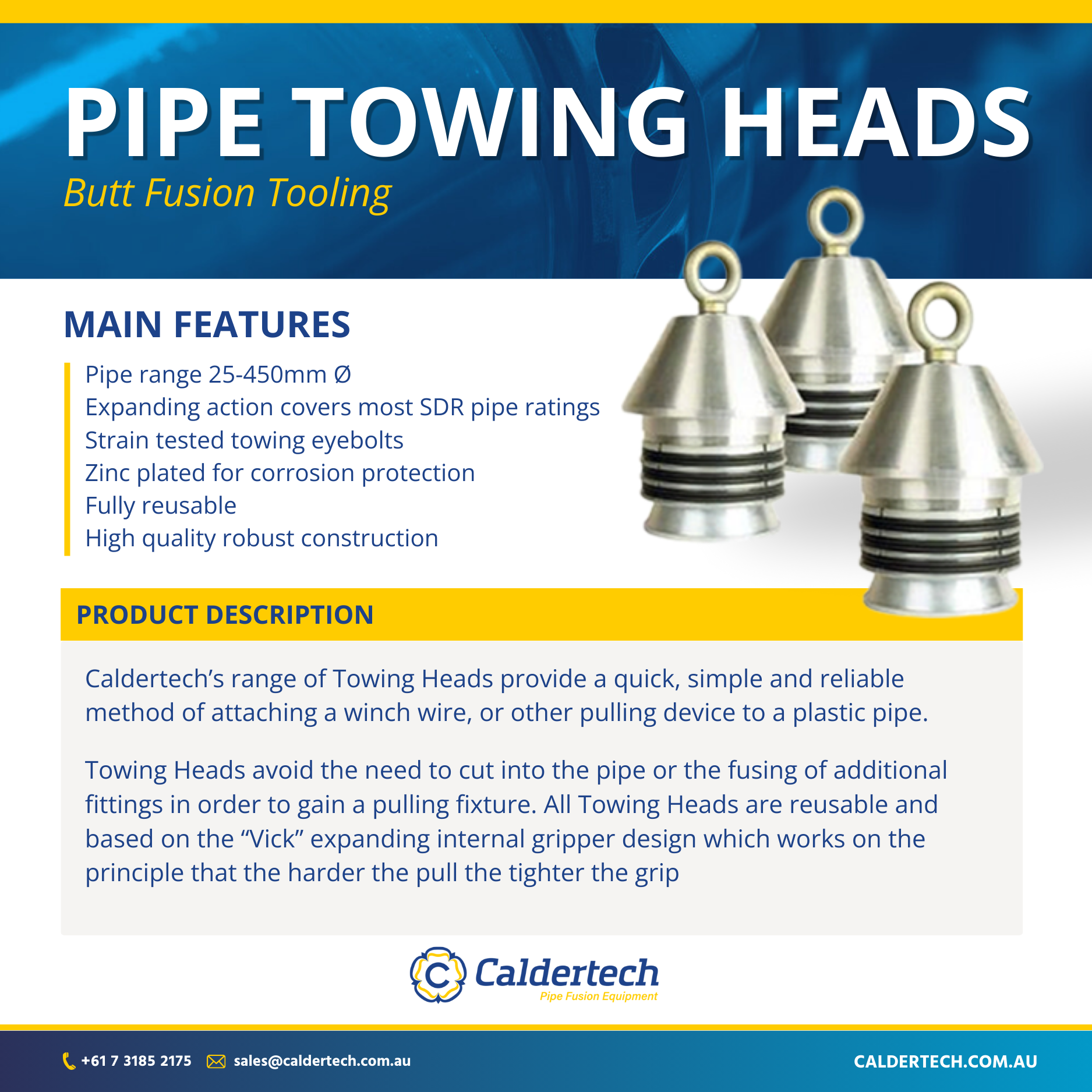

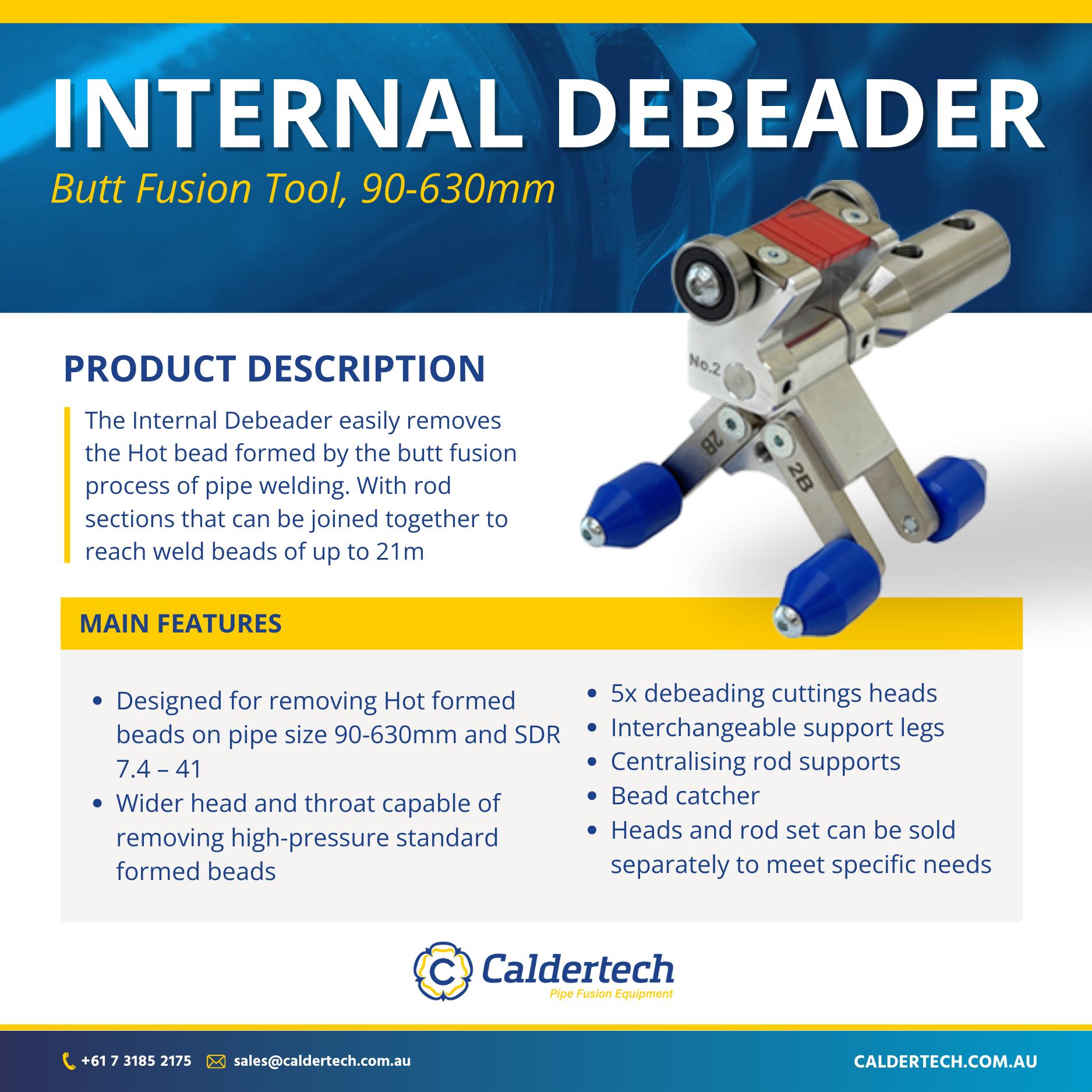

Below are the commonly used Polywelding products from Caldertech Australia.